In the dynamic and ever-changing world of logistics, cubing stands as a determining factor in the efficiency and profitability of transportation operations. From optimizing cargo space to reducing costs and emissions, cubing plays a crucial role in the global supply chain.

What is Cubing?

Cubing is an important tool for competitiveness in logistics and refers to the measurement of the volume occupied by a load.

Cubing is crucial to guarantee and optimize storage and transport space.

Logistics cost is a critical factor in defining the selling price of a product, so cubic capacity can become a variable that increases or decreases prices for companies and maximize their resources in all aspects from trucks, containers, warehouses, etc,

Cubicar Benefits

- Better use of available space within the means of transport is guaranteed.

- Reduced storage and transportation costs

- Increases operational efficiency through better planning and organization

- Maximum use is made of the cargo capacity of the means of transport, thus reducing the transit time for shipments.

- Decreased loading and unloading time

- Reduction of containers and/or boxes for transportation, which translates into a better use for the environment.

What are the main problems caused by poor cubing?

- If the container is overloaded to the maximum capacity it can support, the terminal may reject it to adapt it to the corresponding weight or to the legal weight allowed by the SCT, which generates extra expenses and loss of time.

- Space is wasted if less cargo is loaded in the container or means of transport making the trip more expensive since the cost would have to be divided by less cargo.

In order to achieve a better utilization at the moment of loading, it is important to always know the measures of the packaging to know how much load we can consider for the shipment of the cargo.

It is important to know that in the logistics world there are two standard pallet sizes, the Euro pallet and the American pallet.

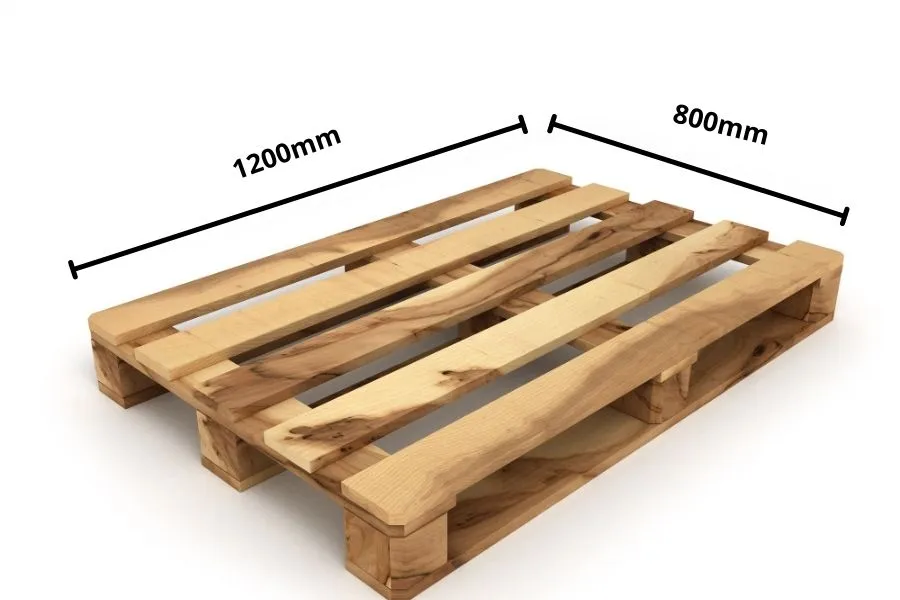

Euro Pallet

The European pallet or Euro Pallet must have a standard size of 1200x800mm. This is due to the fact that the European railroad width is 2400mm. In this way, the available space can be better used and optimized. In relation to weight, a Euro Pallet weighs about 25 kg distributed in wooden boards, usually pine, due to its great resistance.

Despite its size, and being made of strong wood, a pallet can withstand loads of up to 1,500 kg, although statically it can even support up to 4,000 kg. If the wood wears out or breaks, EPP members are responsible for removing them from circulation.

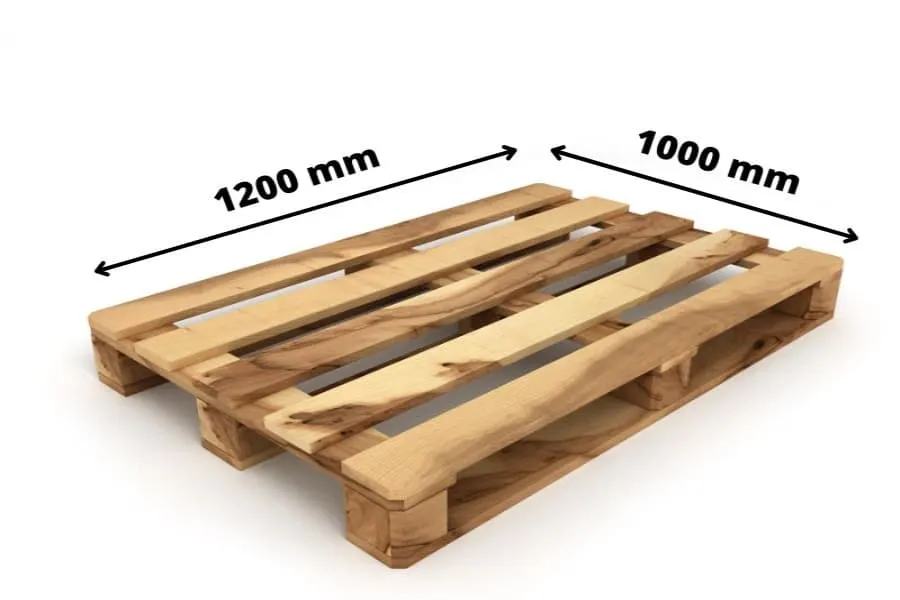

American Pallet

The American pallet is manufactured under the international standard known as ISO 3676. It is used especially in the United States and Japan and, due to its adaptation to the products from these places, it is very popular all over the world for the transportation of goods. It has standard dimensions of 1200×1000 mm. It usually weighs about 30 Kg and with respect to the weight it supports, an American pallet can support loads of up to 1,500Kg, when it is static the supported loads can reach 4,500 Kg.

One of the most important advantages of the American pallet is that thanks to its high resistance, this type of pallet is perfect for the transport of liquid goods.

Once we know which pallet to choose depending on our cargo, we will know the importance of the load arrangement always considering stowable or non stowable cargo, this is an important factor to determine the number of pallets to use.

If we need to cube the space occupied inside a container or box, it is necessary to know its internal measurements, then we will use the following formula:

length x width x height

In this way we will obtain the volume of the load, as a next step we will divide the dimensions of the container or box and we will divide them by the dimensions of the load to know the number of load to be transported.

If the cargo consists of boxes of different sizes, they should be measured one by one. In this way the loads are usually consolidated, as well as knowing the weight of the cargo so as not to overload the container.

In the world of forwarder logistics, knowing the chargeable weight for air movements and Cbm for sea movements is essential to guarantee and optimize costs to customers. And we must know the following:

Cubic Meter (CBM – Cubic Meter)

This measurement is obtained by multiplying: Height x Width x Length in meters of the package(s) considering also the pallet (pallet) if it is part of the load.

Example:

VOLUME (m3) = Length (m) x Width (m) x Height (m) = 1.2 x 0.8 x 1.9 m = 1.82 m3.

Chargeable Weight

To begin with, we must know the difference between the types of weights:

Gross Weight: This is the total weight of the shipment including packaging.

Weight Volume: Is the bulky cargo in relation to its gross weight.

We must check which is greater, the gross weight or the volume weight.

This factor is used by all airlines and is used to determine whether to charge based on Gross Weight or Volumetric Weight, whichever is greater.

In an increasingly globalized and competitive world, cubing is becoming a fundamental tool for optimizing resources, improving logistics efficiency and reducing costs. Recognizing the importance of calculating the volume of the objects we transport is not only a trend, but an imperative need in today’s world. Implementing strategies that consider cubage will allow us not only to adapt to market demands, but also to contribute significantly to environmental sustainability and the development of a more efficient supply chain. In this sense, understanding and valuing the relevance of cubing is an important step towards innovation and progress in an increasingly dynamic and demanding world.